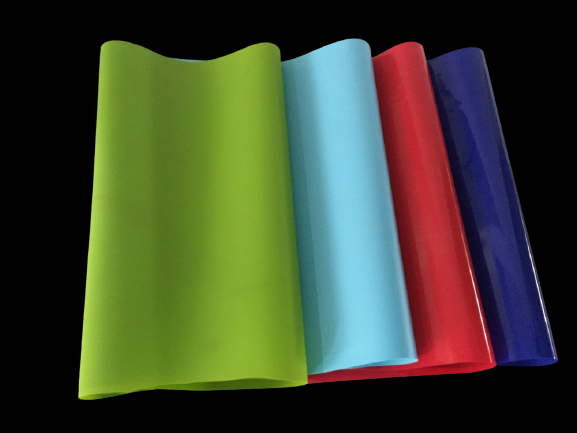

TPU

TPU material (Thermoplastic Polyurethane) is a thermoplastic polyurethane elastomer with many excellent properties and is widely used in many fields. TPU is a (AB)n type block linear polymer, in which A is a high molecular weight polyester or polyether, B is a diol containing 2 to 12 straight-chain carbon atoms, and the AB segments are connected by diisocyanate. This material has a weakened intermolecular force in the molten state or solution state, and can restore the original solid properties after cooling or solvent evaporation, which is reversible.

Processing method

3D printing

- Fused deposition modeling (FDM): The 3D printing field mainly uses FDM technology to 3D print TPU materials. The working principle of the FDM process is to use a heat source to melt the filamentary material, and use a three-axis control system to move the fused material, stacking layer by layer to form a three-dimensional entity.

- Selective Laser Sintering (SLS): SLS is an additive manufacturing technology that uses a high-power laser to sinter small particles of polymer powder into a solid structure based on a 3D model, suitable for rapid prototyping to small batch production.

- Digital light stereolithography (SLA): SLA is an additive manufacturing process in which a light source solidifies liquid resin into hardened plastic, providing high resolution and accuracy, clear details, and smoother surface finish

Post-processing

- Annealing: TPU products often produce internal stresses due to uneven crystallization, orientation, and shrinkage. In order to eliminate these internal stresses and improve the mechanical properties of the product, annealing can be performed. The annealing temperature depends on the hardness of the TPU product. Products with lower hardness can be left at room temperature for several weeks, and items with a hardness below Shore A 85 can be processed at 80°C for 20 hours.

- Surface treatment: For the surface treatment of TPU parts, the surface needs to be cleaned first, and impurities such as dirt and grease need to be removed with detergent or alcohol. The cleaned surface needs to be dried to ensure the coating effect and adhesion.

- Spraying or coating: Apply a specific coating liquid, such as a flame retardant coating liquid, to the treated surface, which can be evenly applied by brushing, spraying or dipping. After coating, it needs to be dried and cured to form a stable coating.

- Post-aging treatment: Post-aging treatment of molded TPU products can better stabilize the size and reduce compression deformation. Changes in product shrinkage should be considered before treatment so that adjustments can be made during mold design.